Product

다올팬텀 제품을 소개합니다.

CT/MRI

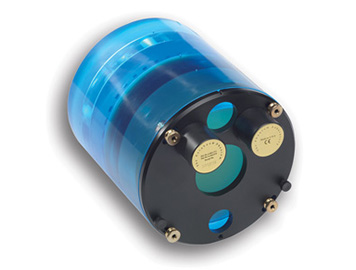

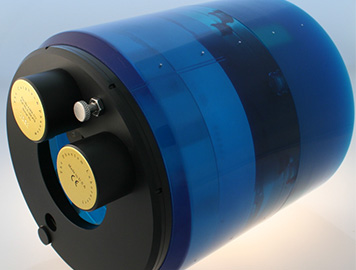

| 제목 | Catphan 600, Quality Control in Radiography / Fluoroscopy |

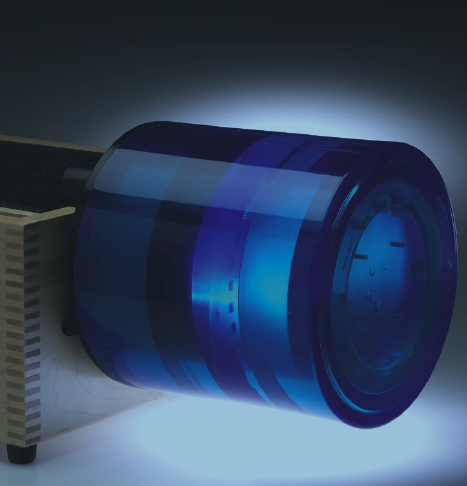

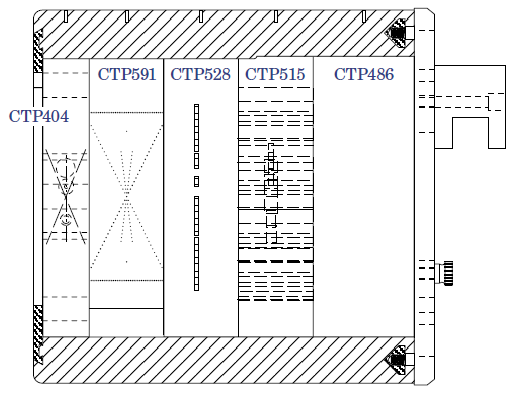

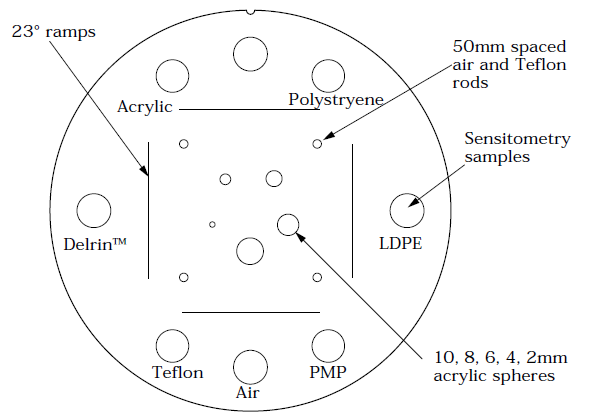

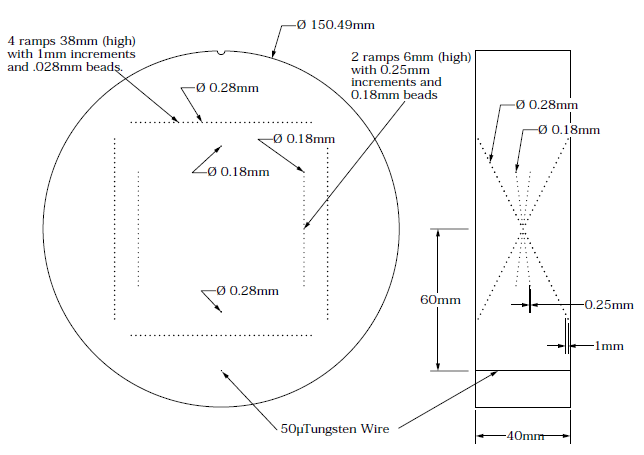

Designed to evaluate the maximum performance potential of multi-slice CT scanners with enhanced sensitometry samples for radiation therapy planning.  Catphan® 600 test module locations: Module Distance from section 1 center CTP404 CTP591 Bead geometry 32.5mm CTP528, 21 line pair high resolution 70mm CTP528. Point source 80mm CTP515, Subslice and supra-slice low contrast 110mm CTP486, Solid image uniformity module 150mm CTP404 Module with slice width, sensitometry and pixel size (Teflon, Delrin Acrylic, Polystyrene, H20, LDPE, PMP, Air)  Slice Geometry and Sensitometry Module Diameter: 15cm Thickness: 25mm • scan slice geometry (slice width) • circular symmetry • phantom position verification • sensitometry (CT number linearity) • patient alignment system check • pixel (matrix) size • scan incrementation The CTP404 test module used in the Catphan® 600 includes sensitometry samples for Teflon, Delrin, Acrylic, Polystryene, LDPE, PMP, Air and a small vial for water. Pixel size can be calculated by counting the number of pixels between the test cylinders in the x and y directions. The module also contains five acrylic spheres to evaluate the scanner’s imaging of subslice spherical volumes. The diameters of the acrylic spheres are 2mm, 4mm, 6mm, 8mm, and 10mm. CTP591 Bead Geometry Module  Bead Geometry Module Diameter: 15cm Thickness: 40mm • slice width for thin slices • slice width for thick slices • MTF and SSP with two size point sources • test on multiple slices in a multi-slice sequence The CTP591 Bead Geometry Module contains both coarse ramps with 1mm z axis increments and precision ramps with .25mm z axis increments. To maintain a strong signal with an appropriate diameter, the coarse ramps use 0.28mm diameter tungsten carbide beads while the precision ramps use 0.18mm tungsten carbide beads. The use of beads enables quick assessment and comparison of slice thickness in a multi-slice sequence verifying consistency across the detector area. The unique ramps are positioned in opposed pairs to eliminate errors caused by non-perpendicular alignment. There are 2 pairs of coarse ramps and 1 pair of precision ramps. The coarse ramps each contain 39 beads, transversing all but the last millimeter of the 40mm module. The precision .25mm ramps each contain 25 beads covering a 6mm range. For detailed MTF and SSP calculations, two isolated beads 0.28mm and .018mm in diameter are located in the mid plane of the module. For thin slice high resolution measurements, a 50μ diameter steel MTF wire runs through the full 40mm thickness of the module. CTP528 High resolution module with 21 line pair per cm gauge and point source  High Resolution Module Diameter: 15cm Thickness: 40mm • scan slice geometry (slice width and slice sensitivity profile) • high resolution (1 to 21 line pairs per cm) • point spread function and modulation transfer function (MTF) for the x, y, and z axes The unique design of the CTP528 minimizes visual artifacts by reducing the amount of high contrast material. The 2mm thick aluminum contrast figures are cast into position on the radial gauge, which has resolution sections ranging from 1 to 21 lines pairs per cm. This radial design pattern eliminates the possibility of streaking artifacts from other test objects. This section, combined with spherical beads – rather than wire – for MTF measurements, allows operators to avoid the tedious and time-consuming step of positioning and aligning MTF wires with the z axis. The point source beads also eliminate the over-ranging problems and streaking artifacts that occur with MTF wires, because the bead density is volume averaged with the surrounding material. CTP515 low contrast module with supra-slice and subslice contrast targets  Low Contrast Module Diameter: 15cm Thickness: 40mm • low contrast sensitivity • comparative subslice and supra-slice low contrast sensitivity The CTP515 consists of a series of cylindrical rods of various diameters and three contrast levels to measure low contrast performance. The 40mm-long rods provide consistent contrast values at all z-axis positions, thereby avoiing any volume-averaging errors as you scan through the section. The unique subslice test objects enable evaluation of the effectiveness of different scan protocols (pitch, slice width and reconstruction algorhythms) in resolving subslice low contrast objects. For selection of helical and multi-slice image protocols, unique subslice low contrast targets (truncated cylinders) have been included in this module. Comparing the images obtained by scanning the subslice targets with different imaging settings (slice width, pitch and reconstruction algorithms) provides valuable information to assist with the selection of optimal protocols for identifying small low contrast objects such as tumors. All of the various samples and the background material have equivalent effective atomic numbers; only the density is varied to produce changes in the effective attenuation coefficients. Subslice targets have a nominal 1.0% contrast and z-axis lengths of 3, 5, and 7mm. For each of these lengths, there are targets with diameters of 3, 5, 7 and 9mm CTP486 Image uniformity module  Uniformity Module Diameter: 15cm Thickness: >40mm • spacial uniformity (noise) • noise (precision) of CT systems The CTP486 does not leak and is not damaged by exposure to freezing temperatures because it does not use water. While water is generally considered the standard calibration material, many physicists prefer using our CTP486 solid-image uniformity module because it provides consistent results, is much more convenient to use than modules using water-filled tanks, and eliminates variations due to different water sources. The CTP486 module is cast from a uniform material that has a CT number within 2% (0-20H) of water. This solid material’s high radial and axial uniformity makes it an ideal substitute for water. It has been thoroughly tested over a wide variety of variables in the x, y and z planes and has proven stable in all applications. |

|

| 카테고리 | |

| 문의하기 |